‘Idiocy’ may be a strong word, but clickbait gonna clickbait. Let’s move on.

I was first introduced to the idea of a pinned & welded AR barrel in about 2011. NFA laws being what they are, a rifle has to have a barrel of 16″+ to not be considered a Short Barreled Rifle (aka, SBR). That rule is oppressive and arbitrary and dumb, but we can work around it.

The US Army uses 14.5″ barrels on their M4 carbines. They can do this, because they are working for the government. It’s the classic “Laws for thee, but not for me”, but that’s irrelevant to this particular post. Why 14.5″? Why not 14 even? Or 15? A quick google search indicates that 14.5″ (with carbine length gas tube) was the shortest length to which they could still attach their bayonets. I have no idea if that is really the case or not, but it’s also irrelevant to this discussion.

The problem occurs when civilians want to be like the military and use what the cool guys use, or returning vets want to continue using what they were issued. The US military issues SBRs as the standard service rifle (technically they’re machineguns, but whatever). Us normal folk can’t run 14.5″ barrels on our rifles unless they are registered as SBRs. That means that we have to fill out registration forms, pay $200 to the government, wait for months, and then what do you have? A rifle that you cannot take across state lines without express, written permission from the ATF. Totally worth it, right?

Eh…

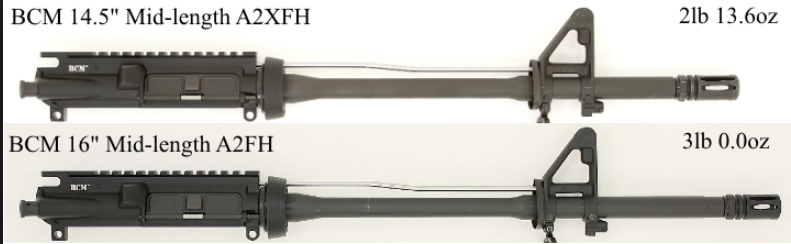

So, what’s a gun bro to do? A lot of people noticed that the military’s standard issue muzzle device, the A2 flash hider, is a little over 1.5″ long. If they permanently attached an A2 flash hider to their barrel, they’d be legal and they’d achieve the look they want. It looks like what the boys ‘over there’ use, it saves some weight & length, and it doesn’t have the ridiculous legal baggage that comes along with an SBR. It’s a win-win. Well, only if you never want to modify the rifle at any point in the future. ‘Permanently attached’ muzzle devices can be removed, but you run a very real risk of severely damaging the barrel, and that’s when you’re paying a gunsmith to do it. To understand that aspect of it, we need to understand what ‘permanently attached’ means.

First, let’s go over how to ‘permanently’ attach a muzzle device. This is usually done by drilling a small hole in the muzzle device (if it doesn’t come with one already), driving a pin into the hole so that the device cannot come off the threads, and welding that pin in place. When you see someone mention a “pinned and welded” barrel, that is what has been done. To remove a pinned & welded muzzle device, it means locating the welded-in pin, drilling/milling out, but not into the barrel threads, and then removing the device. I’m not a fan of this method. Here’s a good write-up of the process by people who actually know what they’re doing.

Another way of attaching a muzzle device is to use 1100°F degree silver solder to attach it, but that’s very uncommon (ATF NFA handbook, page 5). I’ve only heard one person mention it, and he was a gunsmith. To remove the device, you would re-heat the muzzle end of the barrel and unscrew the device once the solder melts. I like this way a lot more than removing a welded pin. Based on the material properties of 4150 Chrome-moly steel and 416 stainless, 1100°F is far enough below the point where you start screwing up the hardening of your barrel, as long as you don’t go much above 1200°F. If you reach 1500°F, you’re going to lose the heat treat of your barrel. Be very careful, and pay a professional to do it when appropriate. I don’t care how cool your M4gery looks with a 14.5″ barrel, you’ll look real stupid when your barrel explodes.

Now that that’s out of the way, why should you care about modifying your rifle? Can’t you just run what the Army runs and be fine? Well, what if you don’t want to run an A2 flash hider? Want to try out a muzzle brake for competition this year? Want to screw on a silencer? Too bad. Between the different handguards different brakes, comps, & flash hiders, the recent rise of QD suppressor mounts, and even the SB Tactical Arm Brace, having a pinned & welded barrel is not optimal. Take free float rails for example. If you (like me) didn’t get MLok on all your rifles, you’re probably wishing you did. If your flash hider is pinned & welded, you have to pay someone to get that handguard switched out, and if you don’t replace the barrel entire barrel, you’re either paying that guy to re-weld that flash hider back in place or filing SBR paperwork.

Pinned & welded a QD suppressor mount to your barrel? That’s not a terrible option. Most people (in the US) who buy a can do so for life. They’ll keep that silencer basically forever. The problem comes when you want to try a different can on that rifle. Unless you buy a new can that’s backwards-compatible, you’re looking at a headache. And if you do, how long will that company keep supporting that QD system? In the future you may just want to buy a new upper entirely and not deal with the hassle, which leads to my next point…

Some people (as have mentioned in the comments below) pin & weld their uppers with the thought process of just buying/building a new upper when they don’t like this one anymore. If you have that kind of cash flow, go for it. I’m nowhere near that kind of financial position, so that’s a complete non-starter for me. I assume that most people reading this are in a similar position.

The muzzle device basically has to come off any time you want to change anything about your upper (besides swapping the entire barrel and gas system together). It’s like the very last thing you put on the gun, and permanently attaching it means that everything else behind it is just as permanently attached. One of the most appealing aspects of an AR is the ability to change it to your liking, permanently attaching your muzzle device completely nullifies that whole aspect. It’s like building Legos with glue.

There are some options for 16″ barrels with muzzle devices machined into the end of them, negating the costs of attaching a device to a barrel and allowing much more rifle/rail/gas block customization in the future. The issue with this concept is that the muzzle device you choose at purchase is literally the only one you can ever have on this barrel, as it is literally part of the barrel. That means swapping to a flash hider instead of a compensator (or vice-versa) requires a whole new barrel. Silencers are completely out of the question. I would not recommend this route to someone unless they really know what they’re getting into, or already have other uppers in their inventory.

Permanently Attached Suppressor

Stop it. Just, stop.

Conclusion

There really isn’t a lot of reason to pin & weld devices on your AR in today’s market. It might have been a good idea back in the day, when there as much less modularity in the AR platform. If you were one of those guys who really wrings every bit of performance out of a rifle, a 14.5″ might be enough length and weight savings to justify NFA paperwork, tax, and wait times, and interstate headaches. But that was back then, not today. With the current availability and legality of SB arm braces and the huge amount of options for customizability you’d lose out on, I just don’t see the value.

There is always the reason of “I just want to”, which is always valid. If you are willing to make the demonstrable sacrifices for the seemingly marginal gains, be my guest. If you are in a place financially where you can just buy whatever you feel like, more power to you. Who knows, you might find that I’m completely wrong and a permanently attached muzzle device is great.

Keep your options open, and I’ll see you on Friday. -S_S

Was that post worth a dollar? Check out our Patreon and help support pro-firearms content online for as little as $1/post. This is not mandatory, but purely voluntary and greatly appreciated. And if you don’t, no worries. Thanks for reading, and check back soon.

Very well done! Thanks for the great read!

LikeLiked by 1 person

Get a mid length gas system 16″ barrel, then your bayonet will fit.

LikeLike

Your opinion is bad and you should feel bad.

LikeLiked by 2 people

Same

LikeLiked by 1 person

Double reverse no take backs. *RUNS TO CLOSET AND LOCKS DOOR*

LikeLiked by 1 person

I respectfully disagree with your views on the pinned 14.5 setup. Your conclusions seem to be drawn from theory and not practice. My 14.5 is noticeably different than a standard 16″ model in both length and weight distribution. There are also a few companies that offer low profile flash hiders pre-attached which allow gas block and barrel nut removal/installation so that your carbine can be reconfigured at any time.

LikeLike

I appreciate you being respectful.

I don’t remember if the low profile preattached muzzle brakes were on my radar when writing this. They definitely change some of my opinions.

LikeLike

I disagree. If you get your upper how you want it then have it pinned and welded you won’t regret it. My 14.5 pinned upper is my favorite. You can run multiple uppers on one lower so it never hurts to have a PW in your collection. Have one upper with a bcm a2x flash hider and if you want to run a suppressor get a new upper.

LikeLiked by 1 person

My favorite upper has a 14.5 mid length light weight BCM barrel. It has a pinned front sight base and a BCM A2x flash hider. The hand guard is a Daniel Defense M4 9 inch rail. I had it sent off to Rainer Arms to have the FSB installed and they pinned and welded it at the same time. I run it with a Aimpoint T2, the entire setup is very light.

LikeLiked by 1 person

I also disagree with this notion. I am in the process of building an upper with an Aero 14.5in barrel with pinned & welded muzzle device. This will be my 14th upper I have built and if I ever want something different, I will simply build IT to add to my collection. This happens to be one of several setup’s that I wish to have and I like the idea of it.

LikeLiked by 1 person

I’m glad you have the financial ability to just build any permutation you fancy. I’m not in your shoes and I need more flexibility from my equipment.

LikeLike

This seems to be mentioned a lot in this blog. Guns are expensive. Thats just the way it is (look at ammo right now in 2021!). Accessories are one of the quickest ways to burn cash needlessly. But the reality is the cost of a new upper really isn’t much. You can add plenty of Accessories to a p&w upper if you started with a good rail system. The only things you can’t easily change are the muzzle device, the rail, or the gas block. Who is changing their gasblock so often that a p&w messes things up? Or a rail system? Buying multiple rail systems but not new uppers is just weird and wasteful imo. As for suppressors, i own plenty of them. The qd attachments and the can itself are really expensive. Figure 800-1200$ for the can, 100-150$ per QD adapter, 200$ tax, 50-100$ for the trust, and 50-100$ for the transfer. So your now running 1200-1700$! If your main concern with a P&W upper is cost then a can is outside your budget.

Personally i think “braces” killed the point of a p&w setup in free states. We will see if that continues to be the case over the next 4 years. A permanently attached suppressor isn’t a bad idea at all if you want a short setup without the brace or sbr cost.

As for the state line issue, thats vastly over stated and typically what someone says who hasn’t actually owned a SBR. Is it a hassle? A little. Is it an actual concern if you want a SBR? No. Is it authoritarian nonsense? absolutely.

LikeLike

I just want to recreate my circa 2004 Iraq rifle in 14.5} without SBR’ing it. Pin and weld is the only way, but I will also never sell it and never put a can on it.

LikeLiked by 2 people

I like that. I need to add that reason in.

LikeLike

Aye, and like John Scott Richardson, I’m reasonably well resourced. I have several other ARs complete or in progress, so this one will be but a simple M4 clone. I’m doing an M16A2 clone also to match my Desert Storm rifle. No pin and weld needed, but that one will also never see a can or muzzle device other than a USGI birdcage.

LikeLiked by 1 person

You have enough money to change your upper configuration on a frequency that makes a pinned muzzle device impractical, but you can’t afford a new upper? You can afford suppressors, but not new uppers? Your cash flow does indeed sound limited. Please let me know where I can send you a can of beans, or a loaf of bread.

I put a little thought into my build before I put it together, and have had no reason to change it.

LikeLiked by 1 person

Changing a hand guard costs a lot less than a whole new upper, especially if you don’t shop at the cheapest place you can find. We all put thought into builds before we build them, but what we think will work for us and how it actually works for us are not always one and the same.

For the new guy who doesn’t know what he doesn’t know, and doesn’t have the cash to be buying new uppers all the time, a pinned & welded muzzle device isn’t the best choice. If you have experience and you know what you like, then go for it.

LikeLike

I just got done building my ultimate rifle last year with all my “stimulus” checks it has a 14.5 in barrel that I was going to pin. But now here it is less than a year later and I got a suppressor so I have to change the handguard. I’m just glad I never got around to pining it

LikeLiked by 1 person

There are also those of who live in terrible states like Massghanistan who require us to pin and weld all muzzle devices (no flash hiders allowed either) no matter the length of barrel and we are also not allowed to have “assault pistols” so braces are out. So for us here behind enemy lines, pinned and welded 14.5″ barrels are quite an attractive option. I would agree with your opinion otherwise.

LikeLiked by 1 person

Did not know that about Mass. That’s unfortunate that you have to deal with that nonsense.

LikeLike

Please elaborate

LikeLike

I 100% agree with the 14.5″ argument as it is only good for clone-esque builds by people who just want “that look” to their rifles. That being said, I can see an argument for 13.7-13.9″ barrels as they are primarily made *for* the aspect of pin and welding a device on there and saving some weight to your build. Not to mention, still being able to keep that midlength gas system, which I personally enjoy running. I love building 13.7″ since I can afford to build them, but I would not recommend it for someone first starting out. 16″ all the way for beginners. Hell, even pistol builds are a better option than 14.5″ pin and welding.

Would love to hear your thoughts on 13.7-13.9″ barrels. Would you consider it a practical option or just another “tacti-cool” trend in today’s gun community?

LikeLiked by 1 person

I think the 13.7 is a bit of a trend, but the handling and mid length system combined make something that has staying power.

LikeLike

I agree with a lot of what you said there maybe reasons for a smaller gun maybe he lives in one of those micro homes and space is tight are he wants to go back packing with it. are he lives in a bus. And to take it off why would you need too if you got a quality gas bock and had it installed never hear about them failing unless its aluminum but nice article

LikeLike

Great article. However, with the impending threat of braces going away (2021), there is a strong argument of why permanently attaching a suppressor to achieve the legal 16” length is a better alternative than registering your AR pistols as SBRs. SBRs are way too controlled and of course there’s the fact that you are submitting to another registration.

LikeLike

This post was written back in the blissful days of Trump’s relatively pro-gun administration. A brace ban will absolutely change the stage of sub-16” barreled guns.

LikeLike

I would agree to the extent that you shouldn’t do a 14.5″ PW on your first or only build (unless impracticality is affordable to you). I have built a couple AR’s that are my work horses and I can do whatever I want to them. But I’m also looking to build an M4 clone similar to my issued rifle. Purely for the sake of nostalgia. That said, I’m still arguing with myself over whether 1.5″ really makes that much of a difference. It’s not like I’m suddenly going to have a hard time getting around corners or door ways because my barrel is 1.5″ longer than it should be. And (I genuinely don’t know) how much different does it really look? Is cosmetic accuracy for the sake of cosmetic accuracy really worth it? Is the difference between a rifle and a carbine really 1.5″?

LikeLike

As the proud owner of a 11.5” pistol, 1.5” isn’t worth the hassle.

LikeLike

I know this is an old post but I just found your site thanks to “Scattered Shots” blog.

I’m not so much in favor of 14.5 P/Ws as much as I’m a hater of 16 inch Carbines.

That barrel sticking out too far is just jarring to me, and a constant reminder of

A 16 inch mid length, 20 inch rifle, or an SBR Carbine, or a 14.5 p/w carbine are all preferable to a 16 inch carbine in my opinion.

LikeLiked by 1 person

Really agree on preference of gas lengths. 16” really do benefit from having a mid-length system. If a pistol or SBR is going to be suppressed, it’d probably benefit from a mid-length too

LikeLiked by 1 person

Thanks , I have just been looking for information about this subject for a long time and yours is the best I have came upon till now. But, what in regards to the bottom line? Are you sure concerning the source?

LikeLike

Lol to all the people who pin & welded having buyer’s remorse and defending their dumb choice.

LikeLiked by 1 person

So, with the ATF ruling that pistol braces convert AR pistols into SBRs, the math has changed. Pin and weld looks much more attractive now that you can’t just apply a pistol brace. I know this article came out years ago, but pin and welding avoids this in general

LikeLiked by 1 person

Due to the current legal limbo that specific ruling is in at the moment, it’s definitely a “I don’t even know anymore”-type situation

LikeLike

This aged well

LikeLiked by 1 person

Like milk! Lol.

LikeLike

I’m seriously considering pin&welding a silencer now because of the brace rule thing. I live very close to a state line and don’t want to deal with the extra BS paperwork of transporting an sbr across state lines.

LikeLiked by 1 person

Until the pistol brace business is cleared up, pin & weld is a viable option. Especially for an edge case (pun intended) like yours, I’d actually go for it.

LikeLike

imagine living in New Germany as i call it and having to pin and weld every rifle. because the threaded barrel is a evil feature. pistol grip evil feature and detachable magazine yep evil feature. And we can only have 2 evil features. So basically every rifle here needs a muzzle brake or compensator pin and welded. Because you guessed it no flash hiders those are not allowed in new Germany.

LikeLike